I. Overview

With the development and application of CNC technology combined with high-performance inverter controllers and servo drive equipment in various production industries, CNC engraving machines have increasingly become the mainstream configuration in today's engraving industry.

The spindle system is an important component of the CNC engraving machine, and its performance has a crucial impact on the performance of the CNC engraving machine. As the heart of the spindle system, the frequency converter is an indispensable key component. This article mainly introduces the application of the frequency converter in the spindle drag system of the CNC engraving machine.

2. Working principle

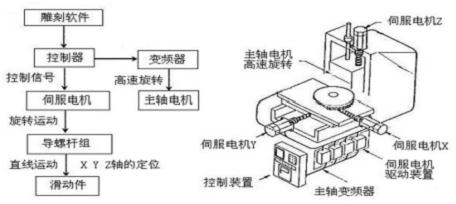

The mainstream CNC engraving machine is composed of a computer, an engraving machine controller, and an engraving machine main body. Its working principle is to design and typeset through special engraving software configured in the computer, and transmit the design and typesetting information to the engraving machine via the computer. In the controller, the controller converts this information into a pulse signal that can drive the stepper motor or servo motor, and controls the X, Y, and Z axes of the engraving cutter on the main body of the engraving machine. At the same time, the controller starts the inverter, drives the engraving head of the spindle motor to rotate at high speed, and cuts, drills and mills the processing material fixed on the worktable of the host, and can engrave various plane or three-dimensional relief graphics designed in the computer. And text, to achieve automatic engraving operations, according to different processing materials and process requirements, can be equipped with different special configuration tools.

雕刻机原理图

3. System configuration

The spindle system is an important component of the CNC engraving machine, and its performance has a crucial impact on the performance of the CNC engraving machine.

6000E series of low-power inverters with its unique super performance and superior cost performance, meet the performance characteristics of the spindle with a wide speed range, high speed stability, strong overload capacity, large low-speed torque, short acceleration and deceleration time, etc. It has a large market share in the domestic engraving machine market.

The engraving machine power supply system has single-phase 220V and three-phase 380V. Most models use single-phase 220V power supply. The frequency source of the inverter uses the 0~10V analog signal output by the numerical control system, and the corresponding operating frequency is 0~400Hz. This method can realize stepless speed regulation of the spindle. According to different engraving objects or engraving processes, the cutting speed of the spindle can be changed in real time. Widely used in high-end and high-end engraving machines that require high and fine engraving technology.

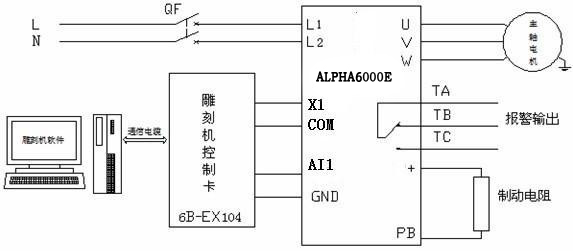

The installation wiring diagram of the inverter is as follows:

The inverter accepts the analog signal of 0~10V output from the controller. This voltage value is proportional to the speed range of the speed setting set by the parameter in the inverter. X1 is the forward rotation signal of the inverter. When the controller sends a forward rotation signal, the output relay on the controller will act and the normally open contact of the relay will pull in to provide a signal to the inverter. L1 and L2 are the power input of the inverter. If the inverter selects three-phase input, it can be connected to the R, S and T terminals. TA/TB/TC is the inverter relay output, usually choose inverter fault alarm output, connect to engraving machine controller or external fault indication circuit.

Four, system advantages

1: 0-650Hz frequency output range, wide speed range

2: Wide voltage design of ±20%, to meet the application occasions with large voltage fluctuation

3: Dynamic torque current control, quickly respond to load changes

4: 8-stage speed can be set to meet the occasions where multi-stage speed is required

5: Compact structure, saving installation space

6: Pass strict EMC test, strong anti-interference ability