The forging and pressing machine that converts the rotary motion of the motor into the linear reciprocating motion of the slider through the crank slider mechanism to form the blank.

I. Overview

The forging and pressing machine that converts the rotary motion of the motor into the linear reciprocating motion of the slider through the crank slider mechanism to form the blank. The mechanical press is stable and reliable, and is widely used in stamping, extrusion, die forging and powder metallurgy processes. It is the most commonly used cold stamping equipment, its structure is simple and easy to use.

2. Working principle

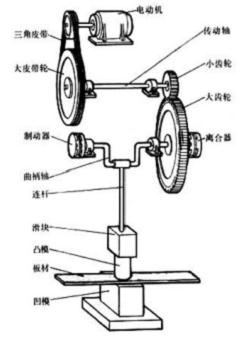

As shown in the figure below, when the mechanical press works, the large pulley (usually double as the flywheel) is driven by the motor through the V-belt, and the crank slider mechanism is driven by the gear pair and the clutch to make the slider and the punch straight down. After the forging work is completed, the slider returns upward, and the clutch is automatically disengaged. At the same time, the brake on the crank shaft is turned on, so that the slider stops near the top dead center.

Mechanical press structure

There is a mechanical or electrical interlock between the clutch and the brake on the mechanical press to ensure that the brake must be released before the clutch is engaged and the clutch must be disengaged before the brake is braked. The operation of mechanical presses is divided into continuous, single stroke and inching (inching), most of which is achieved by controlling the clutch and brake. The stroke length of the slider is unchanged, but the distance between the bottom surface and the worktable surface (called the sealing height) can be adjusted by the screw.

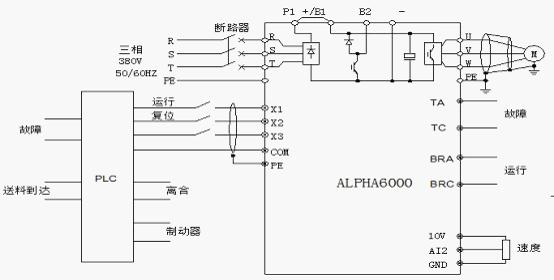

3. System configuration

Disadvantages of traditional presses:

1. Because the motor is always in the state of power frequency movement, the number of workpieces processed per minute is fixed, and the peripheral processing equipment of the punch is not used to realize the automatic processing function.

2. Since each processing cycle has to go through the necessary steps of clutch action-stamping-brake action, the processing efficiency is low, and the clutch and brake are easy to wear.

3. Since the speed of the flywheel is not adjustable, the impact energy is fixed, and the "big horse-drawn carriage" phenomenon is wasted when processing small pieces, wasting energy.

4. When the motor is started and stopped, it will have a big impact on the power grid and machinery.

In view of the above situation, along with the mature and popularized performance of the inverter, we have proposed a modified solution.

Frequency conversion:

In view of the conditions of large impact of mechanical presses and short strokes, we selected 6000 series inverters for transformation

Four, system advantages

The 6000 series is an inverter specially designed for heavy-duty loads, which has the following main features:

u Advanced software algorithm and high control accuracy

u Good low frequency characteristics, torque can be automatically increased

u Strong overload capacity, up to 200% overload current

u The running curve can be customized according to the load requirements

u With S curve acceleration and deceleration mode, it can prevent the impact on the load during acceleration and deceleration

u Excellent product technology, adapt to harsh industrial environment

Advantages after transformation:

1. After the frequency conversion is installed, due to the adjustable stamping cycle, it is very convenient to match with the feeding equipment to form automatic processing.

2. During normal operation, the clutch and brake no longer act frequently, which extends the service life of the brake and clutch and reduces maintenance costs.

3. Since the flywheel speed is adjustable, it is equivalent to the adjustable stamping energy. When processing small workpieces, there is no waste of energy and energy is saved.

4. Start, run smoothly and without impact, prolong the service life of the machine.

5. In case of abnormality or overload, the inverter stops output to protect the motor and machinery.