Electric screw press is a forging equipment with strong process applicability.

I. Overview

The electric screw press is a forging equipment with strong process applicability. It has the characteristics of versatility, simple structure, easy adjustment and maintenance, no bottom dead point of the slider, easy mold design, and high precision of forgings. It is suitable for all kinds of precision forging, finishing, fine pressing, embossing, rectifying, and equalizing procedures. The electric screw press can be used not only for hot forging, but also for precision forging and finishing; it can be used for the pressure welding process of stainless steel double-bottom pot, as well as the precision forging of titanium alloy blades and other blades.

The working process is that the motor drives the flywheel of the screw press through the primary gear, the sleeve shaft and the nut frequently move forward and reverse, the nut and the screw form a movement, and the nut drives the screw and the slider to move downward, when the slider contacts the workpiece , The stored rotational kinetic energy is converted into impact energy, and the workpiece is hit by the slider to deform it. After the impact, the motor drives the nut to reverse, driving the slider up and back to the original position.

2. Working principle

The current main driving methods of electric screw presses are as follows:

1. DC speed control system driver:

The drive system is driven by a DC speed-regulating motor, and the movement speed of the slider is adjusted by adjusting the motor speed, so as to achieve the purpose of adjusting the impact energy, that is, the stamping pressure.

Its advantages are smooth speed regulation, wide range of speed regulation, and large torque at low speed. The disadvantage is that the DC speed regulation system has a complicated structure and a large volume, and the carbon brush needs to be replaced regularly, and the use and maintenance cost is high.

2. AC servo system driver:

The servo motor directly drives the nut to move, adjusts the motor speed, and also achieves the purpose of adjusting the stamping pressure.

Its advantages are simple structure, less maintenance, and high control accuracy. The disadvantage is its high cost, which is limited by the torque of the servo motor and cannot be applied to large-tonnage presses.

3. System configuration

With the rapid development of frequency conversion technology in recent years, its driving performance is becoming more and more perfect, and it has been widely used in many occasions.It has the advantages of wide speed range, small size, low cost, and can be used with other equipment to achieve automatic control. Frequency conversion speed regulation is a better driving scheme.

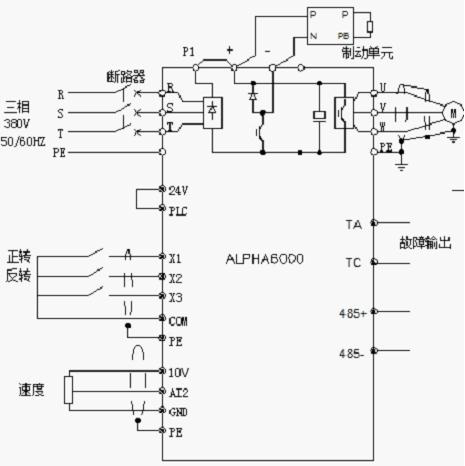

As shown in the figure below, the positive and reverse can be connected to external devices such as PLC to form an automatic control function; the movement speed of the slider can be adjusted by the potentiometer to adjust the stamping pressure; in addition, it can also communicate through 485+,485- It is connected to the host computer or touch screen for start and stop control, and through the recipe function of the host computer, the process parameters of different processed products can be set. Users can flexibly choose the control scheme according to their own situation.

In addition, a braking unit is arranged in the main circuit to ensure that the motor can be quickly stopped, and the switching time of forward and reverse rotation is greatly shortened.

Four, system advantages

u Use 32-bit CPU for motor control

u Dynamic torque current control, fast response to sudden load changes

u High speed control precision, easy to realize high precision control

u Rich input and output interfaces, easy to connect with other devices

u Strong overload capacity, 200% instantaneous overload current protection

u Up to 36 kinds of perfect protection and alarm functions

Advantages of frequency conversion drive scheme:

1. The structure of the whole system is simple, it can be driven by a general speed-regulating motor or asynchronous motor, and the cost is low.

2. After adopting frequency conversion speed regulation, the whole system starts, stops, commutation is smooth, no impact, can extend the maintenance period and service life of the mechanical part.

3. The inverter has rich input and output interfaces and supports standard MODBUS protocol, which is convenient to form a fully automatic control system with the host computer.

4. The protection function of the inverter is perfect, and the output is stopped under abnormal conditions to achieve the protection function of the motor and machinery.

5. The inverter can drive the motor to stop or run at low speed during the gap of replacing the processed parts to achieve the purpose of saving energy.

ALPHA series frequency converter is a frequency converter using magnetic flux vector control mode, which has the following characteristics:

1. The structure of the whole system is simple, it can be driven by a general speed-regulating motor or asynchronous motor, and the cost is low.

2. After adopting frequency conversion speed regulation, the whole system starts, stops, commutation is smooth, no impact, can extend the maintenance period and service life of the mechanical part.

3. The inverter has rich input and output interfaces and supports standard MODBUS protocol, which is convenient to form a fully automatic control system with the host computer.

4. The protection function of the inverter is perfect, and the output is stopped under abnormal conditions to achieve the protection function of the motor and machinery.

5. The inverter can drive the motor to stop or run at low speed during the gap of replacing the processed parts to achieve the purpose of saving energy.