The tension control of the film during slitting and rewinding refers to the ability to permanently control the tension of the film when it is transported on the equipment. This tension control must be effective for any operating speed of the equipment, including acceleration, deceleration and uniform speed of the equipment. Even in an emergency stop situation, there should be the ability to ensure that the slit film is not damaged.

I. Overview

The tension control of the film during slitting and rewinding refers to the ability to permanently control the tension of the film when it is transported on the equipment. This tension control must be effective for any operating speed of the equipment, including acceleration, deceleration and uniform speed of the equipment. Even in an emergency stop situation, there should be the ability to ensure that the slit film is not damaged. The stability of the tension control is directly related to the quality of the slit product. If the tension is insufficient, the film will drift during operation, and the finished paper will wrinkle after slitting and rewinding; if the tension is too large, the film will be easily pulled off, which will increase the end of the finished product after slitting and rewinding. So the winder must have a good tension control system.

Second, the process principle

The control of the winding roller mainly includes speed control and tension control. When the film is wound, as the diameter of the parent roll increases, if the speed of the winding roller remains unchanged, then with the increase of the winding linear speed, it will inevitably cause the winding tension to increase, (because the film sent from the traction device The speed is constant), which will not only cause the inner and outer tightness of the film roll, the outer film will crumple the inner film, but also increase the difficulty of rewinding during slitting, affecting the slitting quality. Therefore, the winding speed of the winding roller must decrease as the diameter of the parent roll increases. It is generally believed that maintaining a constant film tension during film winding is most beneficial to the apparent quality of the finished film. But in fact, because there is a certain amount of air (12% to 18%) between the film layers, even under a constant tension, the outer film will crimp the inner film. The method to solve this problem is to automatically attenuate the film tension according to a certain rule as the diameter of the mother roll increases. Generally, the tension attenuation value under different diameters needs to be input into the computer before winding. During the production process, the operator adjusts the film winding at any time. When the film is changed, the film changes to a new surface of the core, the diameter of the roll changes suddenly, the speed of the winding roller and the rotational inertia of each system change greatly, causing a sudden change in tension, so that the phenomenon of film breakage often occurs. Therefore, in the tension control system of the film, a tension compensation device must be provided to achieve soft start and soft stop, and to prevent wrinkles from being generated on the rolled film.

3. System configuration

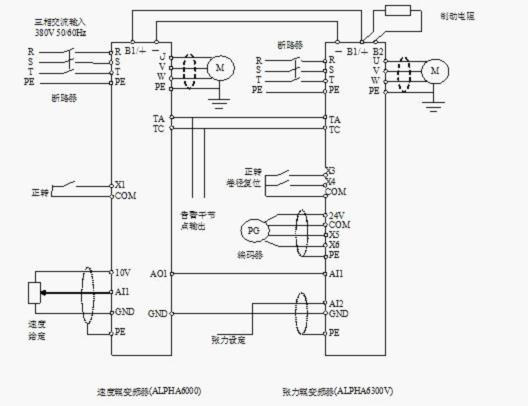

The 6300V frequency converter is a special frequency converter designed based on 6000V series general frequency converters, specifically designed to improve the winding needs of tension control in the drawing, printing and dyeing, textile and other industries, precise torque control, and rich and flexible configuration solutions. So that it can meet the winding needs of various industries such as printing, roll dyeing, steaming and so on.