Wire drawing machine is one of the key equipment for manufacturing steel rope. However, the high reliability of the equipment is an important factor in determining production efficiency and product quality.

I. Overview

Wire drawing machine is one of the key equipment for manufacturing steel rope. However, the high reliability of the equipment is an important factor in determining production efficiency and product quality. The 6000 series inverter has become their preferred brand. Practice has proved that the excellent quality, performance and function of Alpha inverter fully meet the requirements of users. Among them, the direct open-loop torque control function used in winding has been highly praised by users.

2. Working principle

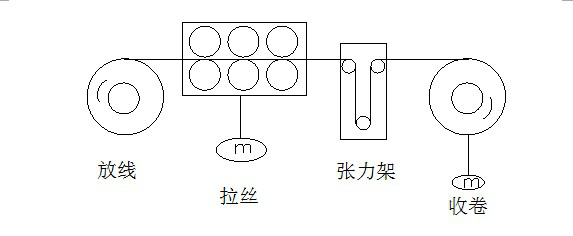

a Pay-off: use passive unwinding or brake to control the unwinding tension.

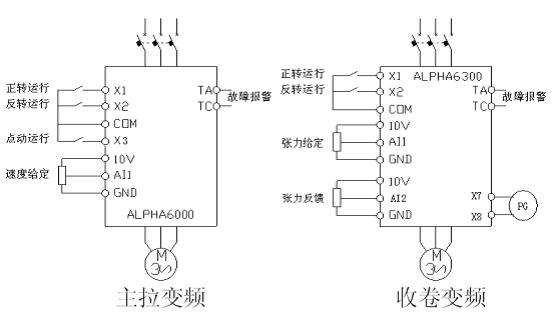

b Wire drawing: it is the main machine, which was originally adjusted by slip motor. The inverter is now used for open-loop speed control. (The slip motor is changed to a common asynchronous motor) The process is to convert the steel wire with thicker diameter, such as steel, copper, iron, etc., into a metal wire with a smaller diameter under the effect of force through a plurality of gradually reduced die holes .

c Rewinding: bundle up the finished yarn. Requires linear speed synchronization and constant tension. The position feedback of the original tension frame (dancing wheel) is used for closed-loop speed control. A special inverter for winding is now used to directly control the winding motor and remove the original tension frame. Directly give an appropriate torque to the inverter that controls the winding motor, the inverter can automatically adjust the output frequency to control the speed of the winding motor so as to achieve constant linear speed and tension.

2 The process flow chart of the original water tank wire drawing machine is as follows:

1 The transmission part of the water tank wire drawing machine is mainly composed of three parts

In the winding control of the middle drawing machine, the electrical control system formed by the 6300 series is stable and highly reliable. The line tension is stable. When the line speed changes, the 6300 series can quickly detect the change in tension and make rapid adjustments. Therefore, the control system can also be directly applied to the wire drawing and winding system with a smaller diameter.

3. System configuration