During the rolling process of cold-rolled steel strip, for the needs of technology, palm oil or similar synthetic oil is usually used as a lubricant.

I. Overview

During the rolling process of cold-rolled steel strip, for the needs of technology, palm oil or similar synthetic oil is usually used as a lubricant. This lubricant will leave an oil film on the surface of the steel strip. When this layer of oil film is annealed in the annealing furnace, carburization and residue formation will occur due to thermal decomposition, which will affect the composition of the steel strip and the surface cleanliness. The quality of order processing. Strip steel degreasing production line is used to remove emulsion marks and iron filings residues, and improve the quality of cold-rolled products by improving the cleanliness of the strip steel surface.

2. Working principle

The function of the strip degreasing production line is to use chemical and electrochemical methods to clean the strip surface to meet the quality requirements of subsequent processing. The electrolytic degreasing unit can also unwind the cold-rolled steel coil, cut off the super thick part of the strip tail, adjust the weight of the steel coil, and take up the coil with a suitable tension. The working process is as follows:

Coiled material->Uncoiler->Inlet hydraulic shear->Lead welding->Inlet tension roller->Alkaline cleaning->Brush cleaning->Chemical degreasing->Brush cleaning->Electrolytic degreasing->Rinse->Hot air purge-> Export tension roller->export hydraulic shear->rewinding->finished product unloading-the steel coil is hoisted to the roll storage by crane.

3. System configuration

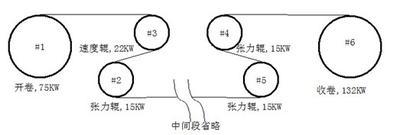

The following figure is a schematic diagram of the process flow of the degreasing raw unit, where #1 is the unwinding, #2 is the speed roller, #3,4,5 are the intermediate tension rollers, and #6 is the rewinding. All 6000V frequency converters were used, but because the non-inductive vector function was not available at that time, both the speed roller and the intermediate tension roller were operating in VF mode, and the principle of speed difference was used to generate force, and the frequency was superimposed to generate tension.