The laminating technology was born in the 1950s and was first adopted by the US Army. The laminating process in my country was inspired by the Japanese calendar in the 1960s, so it was successfully tested in printing and was soon widely used.

I. Overview:

The laminating technology was born in the 1950s and was first adopted by the US Army. The laminating process in my country was inspired by the Japanese calendar in the 1960s, so it was successfully tested in printing and was soon widely used.

2. Process flow:

According to the different raw materials and equipment used, the film printing method of paper can be divided into three types: coated film, pre-coated film, and water-based film.

That is, the film adhesive of the film used in the film coating process is applied. The adhesives used are solvent-based and emulsion-based, which can be prepared at any time. That is, there are many preliminary preparations for the operation of coating the film. The first is the metering of the solvent and solution to make them fully mixed. Then raise the temperature of the drying tunnel of the laminating machine, and then adjust the wind speed, temperature, air volume and the pressure and temperature of the pressing roller in the drying tunnel. After all the preparations are correct, carry out the laminating operation. After the laminating is completed, the laminating machine should be fully cleaned with Tianna water. The process is as follows: plastic film unwinding-traction-glue application and coating-drying in the drying tunnel-paper printing press Membrane-finished product winding.

3. System configuration:

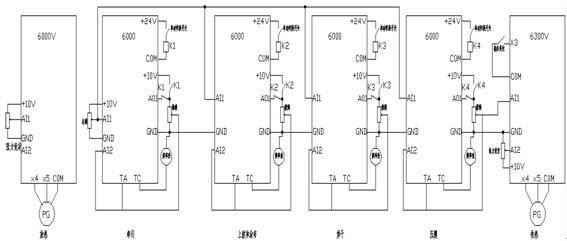

6000V is used for unwinding, 6300V series high-performance vector tension inverter is used for rewinding, and there is a transmission motor for each other link using 6000 series inverter. The motors of each link are 1.5KW, 2.2KW, 3.7KW, 3.7KW, 3.7KW, 2.2KW. Requires a main potentiometer to be tuned, each other link is individually adjusted by a potentiometer, and each link is controlled by a single-acting and linkage switch to control the speed of the potentiometer by a fine-tuning potentiometer. In order to prevent the frequency meter from having no operation Display, so it is controlled by TA, TC terminal (operation).

The system wiring diagram is as follows:

Four, system advantages:

In the whole system, 6000 series magnetic flux vector control is adopted in the middle link, the synchronous speed is stable, the control is simple through coarse adjustment and fine adjustment, the unwinding and winding inverter adopts 6000V and 6300V high-performance current vector inverter, and the tension is stable according to the set tension The product rolled out is shiny.