In recent years, industrial washing equipment has been dominated by water washing equipment in particular, and the application of frequency converters has become more and more popular. The frequency converter has therefore brought a new technological revolution to industrial washing equipment, from the earliest non-adjustable semi-automatic washing machines to use. Two double-speed motors are used to realize a four-speed fully automatic washing machine, and finally developed into a modern washing machine that can achieve multiple speeds with only one motor.

I. Overview

Industrial washing machines require the inverter to provide high torque, multi-speed, wide voltage range, automatic slip compensation and convenient communication methods; stable performance, can adapt to the high temperature and high humidity environment of various hotels and hotel laundry rooms; inverter Suppliers can provide timely and perfect services. In short, the inverter is required to adapt to the specific washing process requirements of industrial washing machines and the service requirements of specific customer groups.

2. Working principle

The washing process of the fully automatic washing machine is as follows:

1.jpg

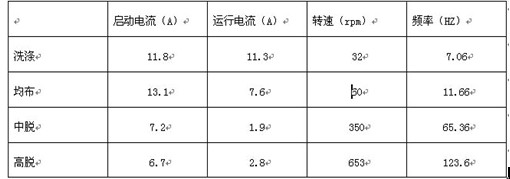

First, add water and wash in forward and reverse rotation for 25 minutes. After washing, drain and enter the dehydration stage. The dehydration stage includes three processes: uniform distribution, medium removal and high removal. Even distribution is in the presence and absence of water. Rotate forward at a higher speed than the washing process for 1.5 minutes to make the clothes evenly adhere to the inside of the drum of the washing machine to make the subsequent dehydration process stable; after draining, increase the speed to enter the medium speed dehydration process (2 minutes), and then enter The high-speed dehydration process (5 minutes) reduces the moisture content of the laundry to the required level.

3. System configuration

There are two ways to set the speed:

1) Set the running speed of each stage directly on the inverter in a multi-stage speed mode;

2) Set the running speed of each stage through a communication computer through a dedicated control computer for the washing machine.

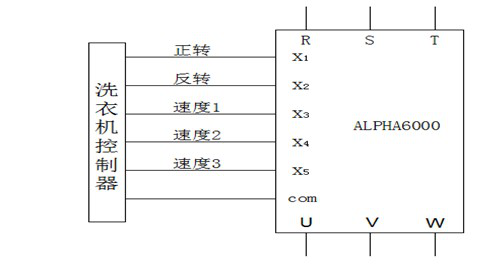

The electrical wiring schematic diagram of the industrial washing machine is as follows. The inverter needs 6000 high-performance vector inverter, which has excellent performance such as large starting torque, smooth operation and perfect fault protection measures.

The above data is obtained through repeated tests. During the period of continuous operation for four hours, there was no abnormal accident, and the temperature rise of the inverter was very small. In addition, similar conclusions were drawn on the 30kg, 50kg, and 70kg models. It can be seen that 6000 inverter is indeed a high-quality inverter suitable for use in washing equipment.