Dehydration machines include secretion machines, centrifuges, etc., which are directly driven by AC asynchronous motors, low-speed feeding, high-speed dehydration; widely used in papermaking, dyeing and finishing, food and pharmaceutical, sugar, chemical and other industries. Modern dehydration machines must meet the needs of different materials using different speeds for dehydration, so the speed of the dehydration machine must be adjustable to meet the needs of the process. In the past, most of them used high and low speed motors. It is driven by another motor, and the mechanical brake is used when the speed is reduced.The transmission system has a high failure rate. Because the high-speed motor has a large capacity and the dehydration tank has a large inertia, the starting current is extremely large and the duration is long. The operating efficiency is low and the speed cannot be adjusted.

One. Overview

Dehydration machines include secretion machines, centrifuges, etc., which are directly driven by AC asynchronous motors, low-speed feeding, high-speed dehydration; widely used in papermaking, dyeing and finishing, food and pharmaceutical, sugar, chemical and other industries. Modern dehydration machines must meet the needs of different materials using different speeds for dehydration, so the speed of the dehydration machine must be adjustable to meet the needs of the process. In the past, most of them used high and low speed motors. It is driven by another motor, and the mechanical brake is used when the speed is reduced.The transmission system has a high failure rate. Because the high-speed motor has a large capacity and the dehydration tank has a large inertia, the starting current is extremely large and the duration is long. The operating efficiency is low and the speed cannot be adjusted.

2. System Introduction

1. Working principle: The centrifugal dehydrator produces centrifugal force through high-speed rotation to achieve the purpose of dehydration. A motor is connected to the bottom of the dewatering barrel. There are many water outlet holes on the wall of the dewatering barrel. When the motor rotates at a high speed, the dewatering barrel will rotate at the same time. The high-speed rotation will generate centrifugal force. Drain out through the water outlet, and out through the drain pipe under the dehydrator.

2. Process requirements

(1). The centrifugal dehydrator is a typical low-damping large-inertia load, which must overcome the over-current phenomenon during the acceleration and deceleration processes during startup.

(2). Accelerate and decelerate with the maximum rated current of the motor, under normal circumstances, the load is not skipped.

(3). The low-frequency torque is large, the starting is powerful, and there is no coasting during parking.

(4). The centrifugal dehydrator generates centrifugal force through high-speed rotation to throw out the moisture of the materials in the stainless steel cylinder. Centrifugal dehydrator is widely used in textile, printing and dyeing, ceramics, chemical industry, mineral processing, hotel washing and other industries.

(5) Wide speed regulation range.

three. System composition

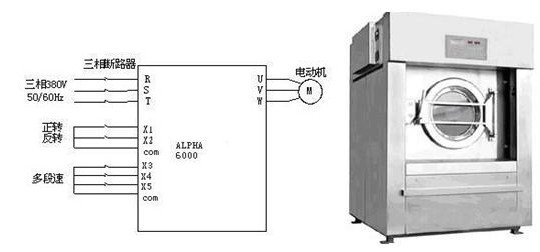

The electrical diagram is as follows

Adopt 6000 series high-performance vector frequency converter, install braking resistor according to the motor power, if the motor power exceeds 15 kilowatts, a braking unit should be added.

4. Effect

1. The equipment control scheme is simple, and debugging, operation and maintenance are convenient.

2. Open loop vector control, 150% rated torque output at 1.0HZ, large low-frequency torque, stable and powerful starting and braking. 3. The DC braking torque is reliable and effective, and the cylinder stops smoothly without slipping within the set time.

4. It can track the start or stop without skipping the current and overvoltage protection in the sliding state of the cylinder.

5. Power grid automatic shutdown function: when the power grid is powered off, the kinetic energy of the rotating large inertia dehydrator cylinder is converted into electrical energy, which is fed back to the inverter, and then heated and consumed through the braking resistor, to avoid the dehydrator caused by the power grid power outage. Free parking, long-time coasting operation.