The glass fiber drawing machine is a mechanical device that melts the glass ball and draws the glass melt into a fiber shape at a high speed and winds it into a fiber roll according to a certain rule. The wire drawing part is mainly composed of crucible, pool kiln, wire drawing machine and temperature control system.

I. Overview

The glass fiber drawing machine is a mechanical device that melts the glass ball and draws the glass melt into a fiber shape at a high speed and winds it into a fiber roll according to a certain rule. The wire drawing part is mainly composed of crucible, pool kiln, wire drawing machine and temperature control system.

figure 1

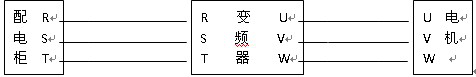

figure 2

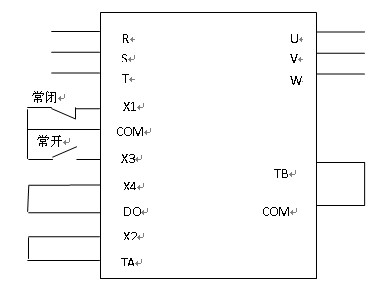

figure 3

2. Working principle

1. Process flow

The process flow of wire drawing machine is divided into several systems:

a. Leakage plate system b. Spray system c. Oiling system d. Bundle system e. Winding system

Winding system: The main equipment in the winding system is the wire drawing machine, and the inverter controls the winding. Its main function is to stretch the glass liquid flowing out of the nozzle of the leaking plate into a certain fineness of glass fiber, and wind it regularly into a raw silk cylinder of a specific requirement by a certain arranging method for use in the next process .

2. Frequency control

Control the glass drawing machine through the multi-function terminals of the inverter, relay output terminals and external lines.

a. When the set frequency and running signal are detected, the inverter will accelerate.

b. By setting the lag frequency, under normal circumstances, the lag frequency of the inverter will be freely stopped after every 1 wire filament is pulled.

c. The inverter decelerates with a deceleration time of 0~6550 seconds. In this way, it can be ensured that the pull-down force is always unchanged under the change of the roll diameter, so that the thickness of the glass filament can evenly meet the production requirements.

d. When changing the coil, the inverter will be disconnected from the running signal instantaneously through the wiring of the external line, so that the hysteresis frequency is recalculated.

3. System composition

1. Main circuit diagram

图4

Note: 1. The winding of the general wire drawing machine is 0.75KW motor, and the 2.2KWG type inverter is selected (used in 2 files)

2. If there is OU overvoltage during free stop, you can choose braking resistor

4. Summary

ALPHA glass wire drawing machine series inverter can make the inverter run at a deceleration time of 0-6550S on the basis of being independent of the maximum frequency, and the system can set the drawing machine to draw a tube of wire, and the operating frequency of the frequency converter falls in the range of Around 10Hz, within this range, a deceleration time of 0-6550 seconds can be achieved by setting the decrement rate parameter. Adapt to the needs of various drawing products. Therefore, the wire drawing effect is more stable, the operation method is faster and simpler, and the waste caused by the operation is minimized. In addition, the motor can be protected in various ways, which greatly reduces the production and labor costs, and significantly improves the production effect.