Fuyang Maoshengda Steel Strip Products Co., Ltd. is a company mainly engaged in the surface treatment of aluminum alloys. At present, the ALPHA6000 inverter has been well received by customers on the aluminum plate double-side polishing machine of the company, and has achieved good results.

I. Overview

Fuyang Maoshengda Steel Strip Products Co., Ltd. is a company mainly engaged in surface treatment of aluminum alloys. At present, 6000 inverters have been well-received and applied on the company's aluminum plate double-sided polishing machine, and have achieved very good results.

2. Components of the polishing machine

The polishing machine is composed of basic elements such as base, polishing plate, polishing fabric, polishing cover and cover.

Third, the working principle of the polishing machine

The motor is fixed on the base, and the taper sleeve for fixing the polishing disc is connected to the motor shaft through screws. The polishing fabric is fastened to the polishing disc through the ferrule. After the motor is turned on by the switch on the base and started, the two motors drag the upper and lower discs, the sun gear, the inner ring gear, etc., and can apply pressure to the sample by hand to rotate On the polishing disc. The polishing liquid added during the polishing process can flow into the square plate placed beside the polishing machine through the drain pipe in the plastic plate fixed on the base. The polishing cover and cover can prevent the dirt and other debris from falling on the polishing fabric when the machine is not in use and affecting the use effect.

4. Control principle and description

Two 18.5KW frequency converters are used on site. 6000 series is a frequency converter using magnetic flux vector control mode. V/F control mode is used. It is easy to install and debug, and can meet the needs of users to the greatest extent.

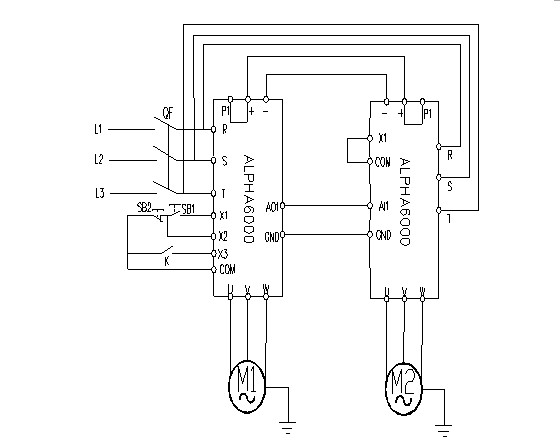

It is controlled by frequency conversion, and the knob on the panel can be adjusted at any speed. The inverter itself has a variety of protection functions such as overcurrent, overvoltage, and overload, which are stable and reliable. The use of a DC common bus for the two inverters can effectively prevent the inverter from reporting an overvoltage fault due to pull-back. The analog output of the motor 1 is used as the analog input of the motor 2 to realize the synchronous control of the two motors. The wiring diagram is as follows: SB1 is the start button, SB2 is the stop button, and the X2 terminal is defined as the running self-holding function.

V. Participating user income

6000 series inverters can meet the needs of customers when they are running at 45HZ. The customer response is also very convenient in operation and use, which improves the efficiency of production and saves electricity. It has the following advantages in use effect:

1. The motor does not need to be started directly frequently anymore, and the frequency conversion technology is used to achieve soft start, which protects the motor and other mechanical equipment well.

2. Under the premise of satisfying the production conditions, 45HZ operation has a certain power saving space to avoid the waste of electric energy.

3. The working efficiency is improved, the speed of the motor can be adjusted arbitrarily according to the production needs, the quality of the product is improved, and the needs of the customers are met.

4. The inverter has various protection functions such as over-current, over-voltage and overload, which play a very good role in protecting the motor.