A high-speed doubling machine used by a parallel yarn factory in Taicang City, this model has compact structure, easy installation and debugging, and simple structure. The failure rate is extremely low, and can achieve mechanical and electrical integration, single spindle control, electronic length measurement, full tube self-stop, electronic anti-overlap, photoelectric

I. Overview

A high-speed doubling machine used by a parallel yarn factory in Taicang City, this model has compact structure, easy installation and debugging, and simple structure. The failure rate is extremely low, and can achieve electromechanical integration, single spindle control, electronic length meter, full tube automatic stop, electronic anti-stacking, photoelectric detection of short yarn, yarn break automatic stop. The 2-3 strands of yarn can be combined into one strand and wound into a cylindrical package. The theoretical maximum linear speed is 900M/min, and the actual maximum linear speed is 850M/min. It is used in cotton, wool, polyester, chemical fiber and Ply processing of blended yarns. At present, the application of ALPHA6000 series inverters on the above simplifies the process requirements and improves the production efficiency.

2. Components and working principle of the spinning machine

The general main mechanism of the doubling machine consists of winding, forming, anti-overlap, and end stop automatically.

Winding part: The bobbin to be wound is pressed tightly on the surface of the bakelite drum rotating at high speed, and the bobbin is rotated by the action of friction to wind the yarn on the bobbin.

Forming part: The traversing yarn guide bar is driven by the forming cam through the rotor and other mechanisms to make a reciprocating motion, so that the yarn guide teeth installed on the yarn guide bar drive the yarn to make a reciprocating motion to complete the cross-winding forming.

Anti-overlap part: In order to make each layer of yarn circle evenly distributed on the surface of the bobbin when overlapping yarns, there is no overlap. Generally, the doubling machine has an anti-overlap device. The anti-overlap devices usually have lever type, belt type, and gear. Style.

Automatic stop of broken ends: when the doubling machine is working normally, the number of plied strands must be kept constant. If a single yarn breaks or a certain bobbin runs out, it is required to stop the winding to avoid insufficient plied strands. The yarn is wound into the package to cause defective products. Therefore, each spindle of the doubling machine is equipped with a set-end automatic stop device. When a single yarn breakage occurs or the bobbin runs out, the automatic stop device of the broken end is triggered to disengage the bobbin from the drum and stop the yarn winding.

3. Control principle and description

ALPHA6000 series frequency converters with magnetic flux vector control method are used in the field. The perfect combination of 485 communication and host computer is used as the frequency reference source of the frequency converter, which can meet the needs of users to the greatest extent.

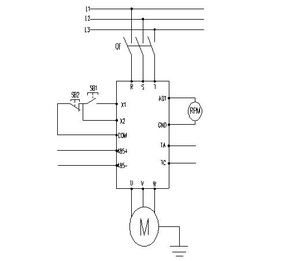

With frequency conversion control, the inverter itself has a variety of protection functions such as overcurrent, overvoltage, and overload, which are stable and reliable. The wiring diagram is as follows: SB1 is the start button, SB2 is the stop button, the X2 terminal is defined as the running self-holding function, AO1 is used as an analog output to display the motor speed, and TA and TC are fault output signals.

4. Conclusion

Alpha 6000 series inverters, low-speed rated torque output, with automatic torque compensation, diverse control methods, built-in RS485 communication interface, flexible operation, energy-saving operation improves motor power factor and motor efficiency, and has the following effects in use advantage:

1. The motor does not need to be started directly frequently any more, and the frequency conversion technology is used to achieve soft start, which protects the motor and other mechanical equipment well.

2. The working efficiency is improved, the operation is simple and convenient, the speed of the motor can be adjusted arbitrarily according to the production needs, the quality of the product is improved, and the customer's needs are met.

3. The inverter has various protection functions such as over-current, over-voltage and overload, which play a very good role in protecting the motor.