Mine hoisting includes vertical shaft hoisting and inclined shaft hoisting. Mine hoisting machine is the key equipment for mine production, which is known as the mine's "throat".

I. Overview

Mine hoisting includes vertical shaft hoisting and inclined shaft hoisting. Mine hoisting machine is the key equipment for mine production, which is known as the mine's "throat". It is responsible for the promotion and decentralization of mine ores, waste rock, equipment, materials, personnel, etc. It occupies a very important position in mine production.

A group company's 3-2 orebody inclined shaft hoist adopts the traditional AC speed regulation method of rotor winding string resistance. The speed regulation method has the following problems: First, more electromagnetic relays are used, and the time for troubleshooting is long. After a long period of operation, the failure rate is high, which not only has high repair costs, but also affects the amount of ore; second, the level of automation of the lift control is low, the noise during operation is high, the temperature of the lift room is high, the lift driver is easily fatigued, and the labor intensity is large; third When heavy weights are continuously lifted at low speed, the resistance generates severe heat and often burns the resistance connection, which consumes a large amount of energy. Fourth, the speed adjustment is stepped, which has a large mechanical impact on the wire rope and reducer.

2. Transformation plan and system composition

1 Transformation plan

The frequency conversion speed control device, programmable logic controller, energy feedback unit, touch screen, etc. are used to form an AC speed control system, replacing the original series resistance speed control system.

2 System composition

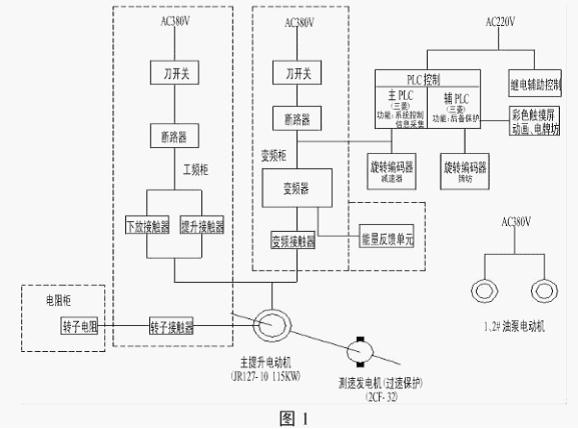

The block diagram of the system composition is shown in Figure 1.

The frequency conversion circuit includes: knife switch, circuit breaker, frequency converter, contactor at the lower end of the frequency converter, energy feedback unit. The energy feedback unit forms a cabinet.

Control loop: Mainly composed of main PLC control, auxiliary PLC control, touch screen, relay auxiliary control, and operation console. Among them, the main PLC control and the auxiliary PLC control are mutually master and backup, the relay auxiliary control, the main and auxiliary PLC control are installed in the same control cabinet, and the touch screen is installed on the operating table as the upper computer. The encoder is installed on the motor and reel as position and speed feedback signals. The speed measuring encoder signal installed on the motor is fed back to the inverter to form PG vector control. Another encoder signal is fed back to the PLC to make speed and position calculations. Speed measuring motor signal, oil temperature and oil pressure signal and other digital signals enter the PLC system

3. Working principle

1 Functions in four states: system stop, manual, automatic and sliding

Stop: In this state, the system stops working, all operations cannot be performed, and the winch is in the brake brake state;

Manual: In this state, when the system meets the requirements for safe operation, according to the parameters displayed on the instrument and touch screen, the master controller performs the normal manual operation of the winch up and down.

Automatic: In this state, the up and down buttons automatically complete the entire process of up and down. When it is halfway through, it can be manually stopped by the stop button and restarted by the up and down buttons.

Sliding: When the system has a serious fault and cannot perform the upward and downward operations normally, the function switch should be switched to this position, and the winch can be slid to the determined position by the main command controller.

Through the double PLC digital control technology, the two-wire winch protection and control specified in the "Coal Mine Safety Regulations" has been realized. The two-wire winch protection and control has the following characteristics:

(1) The speed regulation accuracy is high, the speed regulation range is wide, and the speed regulation accuracy is not less than 0.05%.

(2) Two-wire system protection: A hardware safety circuit and two software safety circuits are mutually redundant, making the system safer and more reliable.

(3) Two-wire system control: during normal operation, due to the mutual monitoring of the dual PLC system, they are redundant. When one of the PLC systems fails, the other PLC system can still be put into emergency driving, which improves the reliability of the winch system.

2 Protection and chain function

2.1 During safety braking, cooperate with the safety valve of the hydraulic station to make the hoist achieve first-level or second-level braking, and at the same time, the inverter enters the feedback braking state.

2.2 In any case, the hoist can only be operated after the driver receives the driving signal.

2.3 When the lubricating oil pressure is too high or too low, the lubricating oil filter or the oil filter of the hydraulic station is blocked or the oil temperature is high, the corresponding fault information is displayed on the touch screen, and the corresponding information lamp is lit to inform the driver This lifting work can be completed, and the driver is allowed to perform the next lifting work only after the fault is removed.

2.4 When the hoist is stopped halfway due to a fault, and the lifting container is located in the deceleration section stroke, after removing the fault, the driver is allowed to choose to drive according to the previous driving direction, and can only drive at a low speed: if the lifting container is not in the deceleration stroke, the wellhead A driving signal is issued to allow the driver to drive at high speed.

2.5 When the whole mine is powered off, the PLC system ensures that the hoist can achieve second-level braking, and the backup protection of the hoist is well done.

2.6 The working braking torque of the disc brake is adjustable. Emergency braking (safety braking) can generate secondary braking to avoid mechanical shock.

3 Stroke control function

The stroke control is completed by the PLC system, which mainly divides the hoisting process of the hoist into stroke sections with different lifting speed requirements. According to the actual situation of each stroke interval and different speed requirements, change the speed setpoint of the inverter, and form a closed loop to smoothly adjust the lifting speed of the elevator: stroke control not only controls the speed of the entire lifting stroke process of the elevator, but also controls the elevator Parking and braking process. Stroke control can prevent accidents such as over-winding, over-discharging, derailment and overturning of the hoist, and is especially suitable for special inclined shafts with bends and forks.

4 Brake control function

The normal braking of the hoist has feedback braking, holding brake and other methods. The realization of the feedback braking is to introduce the inverter link in the DC link of the AC-AC voltage inverter. When the actual operating speed of the hoist is higher than the given operating speed, the motor is equivalent to a generator, the DC link voltage increases, provides energy to the inverter and feeds back to the grid, and the motor automatically runs in the braking state

state. In order to achieve the purpose of accurate stop of the inverter, it can well prevent mechanical shock and rapid decline. The holding brake is generally used during parking. When it reaches the parking position, the stroke controller sends a stop signal to the inverter, and at the same time, sends a holding brake control signal to the holding brake to implement the holding brake. When an accident such as derailment occurs, the operation control implements emergency brake braking.

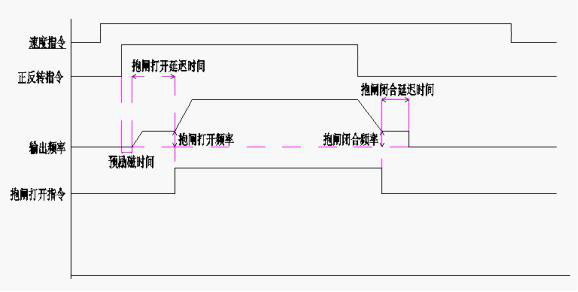

The feedback braking method adopted by this system, during the braking process, the hoist runs smoothly, and the braking energy is fed back to the net, which has a certain energy saving effect. 6920V braking sequence is as follows

5 Main device functions

5.1 Programmable controller function

Except for the emergency protection function, all the control of the system is performed by a programmable logic controller ((PLC. The programmable logic controller configured by the system adopts the ability to adapt to harsh industrial environments and has strong anti-interference ability; it has two communications that can be used simultaneously Port (programmer port and general-purpose port), through communication with the LCD touch screen, can intuitively and conveniently display the system running status, fault status, operation

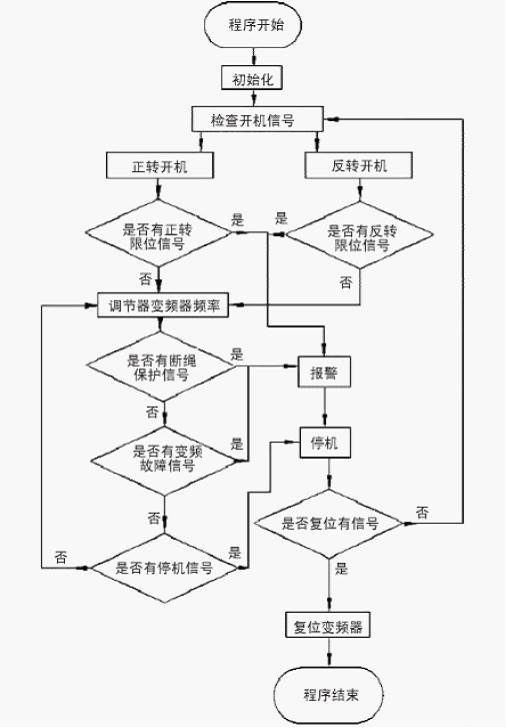

Line parameters, which can display the status of all switching elements and various faults and alarm information; receive signals from the voltage transmitter, current transmitter, encoder, etc. configured by the system, and after operation and processing, control the winch , Monitoring and protection. During emergency braking (safety braking), the programmable controller controls the disc brake to generate secondary braking to avoid mechanical shock. Simplify the control flow chart of the system programmable controller, as shown in Figure 2.

5.2 Inverter function

The frequency converter receives the speed feedback signal from the rotary encoder to form the PG vector control to realize the stepless speed regulation of the motor. This system is equipped with 6920V series inverter and energy feedback unit,

■Integrated scheme: adopting the organic combination of motor drive and lifting logic control, eliminating the PLC in the original system, reducing potential failure points, simplifying system wiring, simple and flexible debugging, and representing the future development direction of crane control;

■Wide voltage design can better meet the harsh power environment

■Professional logic design of cranes: Based on years of experience in the design of the crane industry, we have designed the control and safety logic of expert-level and widely used lifting mechanisms, including timing coordination, anti-slip hooks, and other functions, to provide perfect solutions for supporting customers. ;

■The feeding system in the mining, metallurgy and road construction industries has a special fixed-length design to make the control safer and more reliable. Accurate torque control: stall prevention function, fault reset and retry function; the addition of a rotary encoder 6900 can achieve full-frequency domain flux current vector control, and the motor maintains 150% output torque at 0.5Hz.

Main technical parameters of frequency conversion device

(1) Input power supply voltage AC304-456V, frequency 50HZ; voltage allowable fluctuation range +/-20%; frequency allowable fluctuation range 48-65HZ;

(2) The output frequency range is continuously adjustable from 0 to 50 Hz;

(3) Rated heavy load output power: 160kW.

(4) Overload capacity 150%, 1 minute; 180%, 20s

(5) Have a high power factor cosφ> 0.98;

(6) During low-frequency operation, there is an automatic torque boost function and slip compensation function to ensure 150% of the rated torque;

(7) The inverter is equipped with over-voltage, under-voltage, over-current, overload, power element overheating and motor lack of equal protection, with a fault memory function, which can retain the function number of the last 5 faults and the parameters of the last fault;

(8) The total harmonic content THD<5%.

Main technical principles

(1) Adopt all digital speed sensor closed-loop vector control to make the system speed range wide and speed precision high. When the inverter is running at low frequency, it also ensures that the rated torque output is more than 150%. The maximum torque is twice the rated torque. The basic principle of vector control is to measure and control the stator current vector of the asynchronous motor. According to the field orientation principle, the excitation current and torque current of the asynchronous motor are controlled respectively, so as to achieve asynchronous control. Purpose of motor torque. Specifically, the stator current vector of the asynchronous motor is decomposed into a current component that generates a magnetic field (excitation current) and a current component that generates a torque (torque current), and the amplitude and phase of the two components are controlled at the same time, that is, control Stator current vector, this control method is called vector control method. In this way, a three-phase asynchronous motor can be controlled as a DC motor, so the same static and dynamic performance as the DC speed control system can be obtained.

The PLC control flow is shown in Figure 2.

5.3 Energy return bun unit

The main function is to improve the braking capacity of the inverter and feed back the braking energy of the heavy objects under the winch to the grid to achieve the purpose of energy saving

5.4 The main functions of the console

The console is equipped with a master controller for manual operation. It can manually adjust the braking force and the speed of the winch. It is also equipped with a manual and foot emergency brake switch to quickly brake when an emergency occurs.

5.5 Functions of LCD touch screen

Through the communication with the programmable controller, the system operation status, fault status, and operating parameters can be visually displayed (such as the speed of the winch, the position of the lifting container, the current and voltage of the motor, etc.), and the status of all switching elements and various faults can be displayed. Alarm times; can modify the programmable controller to change the internal parameter settings (need to have the corresponding power: with password protection function can set and modify the operator password according to the authority. Operators of different security levels have different operating rights

4. System configuration

1 Inverter selection

The motor driven by the inverter is: JR 127-8 115k W

Rated voltage: 380V

Master current: 227A

According to: the principle of inverter rated output current ≥ motor number constant current × 1.1

227×1.1=249.7A

Check the sample of 6920V series inverter:

The rated output current of capacity 132kVA is: 255A

The rated output current with a capacity of 160k VA is: 302A

Comprehensively considering the environment and transportation conditions under the pit, the final selection of the inverter capacity is I60kVA

Model: 6920V-3160G

2 Programmable controller selection

Comprehensive consideration of upper roll, lower roll, manual up, manual down, automatic up, automatic down, normal stop, emergency stop, safety circuit, hydraulic station control, disc brake control, work indicator lights, report indicator lights, etc. . And the interlocking control between each working condition. And consider a certain redundancy. Finally, the programmable controller was selected as the Mitsubishi brand, with 48 points.

Model: FX2N-48M-001

3 Selection of energy return bun unit

3.1 Braking voltage selection

The brake voltage is selected too low. When the grid voltage rises, it will cause the brake unit to malfunction. If the brake voltage is selected too high, it poses a threat to the safe operation of the equipment. For a 380V system, the brake voltage is generally 700V.

3.2 Braking current selection

The braking current refers to the DC current flowing through the braking resistor and braking unit during braking.

Selection basis: The brake must completely absorb the regenerative electric energy of the motor

Brake absorbed power (U×I)=motor regenerative electric energy (watt)=1000×P×η

P____Rated motor power (kW)

U____DC working point of braking unit, usually 700V

I____ Braking current (A)

η____ Conversion efficiency of mechanical energy during feedback, usually η=0.7

Calculated: I=115

3.3 Power selection

Motor regenerated electrical energy must be absorbed and fed back to the grid

PR=P×Kf×η×ε

PR————Power of feedback unit (Kw)

η____ Conversion efficiency of mechanical energy during feedback, usually η=0.7

ε____ Safety factor for braking power consumption. Take ε = 1.4

Kf____braking frequency refers to the proportion of the regeneration process to the time of the entire motor working

Check related information Kf take 60%

Calculated PR = 67.62 kW

Select the power of the feedback unit 70 kW

V. Transformation income

1 Running effect

After the system is put into operation, the winch is easy to operate and runs smoothly, and the ambient temperature and noise of the winch control room are greatly improved. Provides a good working environment for operators

2 Energy saving effect

From January to May 2008, the unit consumption increased to 2.92 degrees/t. From January to May 2009, the unit consumption increased to 1.66 degrees/t, the unit consumption decreased by 1.26 degrees/t, and the unit consumption decreased by 43.15%. 132,334 tons, saving 167,700 kWh, the comprehensive electricity price is calculated at 0.528 yuan/kWh, and the annual electricity cost is reduced by 88.04 million yuan.

In short, the application of the frequency conversion speed regulation system in the underground hoist system can solve the problems of speed regulation and start-up, realize soft start and soft stop, reduce the mechanical impact and make the operation more stable and reliable; start and accelerate the shift When the impact current is very small, the impact on the power grid is reduced, the operation is simplified, and the labor intensity of the workers is reduced; the running speed curve is S-shaped, which makes the acceleration and deceleration smooth and no impact; the safety protection function is complete. In addition to the general overvoltage , Undervoltage, overload, short circuit, temperature rise and other protection, interlocking protection, automatic speed limit protection, etc., and the use of frequency conversion speed regulation system instead of string resistance speed regulation system in the pit down winch is to improve the mine pit The technical content of the winch of the inclined shaft, and open up a new way to tap potential for energy saving.