For the oilfield water injection pump motor, some self-coupling depressurization start control is used, which has a large starting impulse current. After stable operation, the water injection pump works for a long time under the condition of power frequency 50HZ, the pressure is adjusted by the valve, and a lot of electric energy is wasted. In order to achieve energy-saving and reliable purposes.

For the oilfield water injection pump motor, some self-coupling depressurization start control is used, which has a large starting impulse current. After stable operation, the water injection pump works for a long time under the condition of power frequency 50HZ, the pressure is adjusted by the valve, and a lot of electric energy is wasted. In order to achieve energy-saving and reliable purposes. Based on years of field experience in the oil field, Alpha has specially introduced a special frequency converter and control system for oil field injection pumps.

Technical characteristics

Using the world's most advanced IGBT power module, the input voltage range allows 20% of the rated voltage to fluctuate up and down, which is suitable for oilfields with such large voltage fluctuations. The frequency converter has a built-in PI regulator and a simple PLC, so that the water injection pump can easily form a closed-loop system for control and maintenance.

Transformation plan

One inverter is used to control 2-3 water pump motors. The maximum motor power is 45KW.

The control process is: when the water consumption is low, use the No. 1 pump of the inverter to provide constant pressure water supply. When the water volume gradually increases, the working frequency of No. 1 pump is close to 50HZ, and its motor is switched to power frequency power supply. At the same time, switch the frequency converter to the No. 2 pump, and the No. 2 pump will supplement the water supply. On the contrary, when the water consumption gradually decreases, that is, the working frequency of the No. 2 pump has been reduced to the lower limit frequency, and when the water supply pressure is too large, the No. 1 pump is turned off, and the working frequency of the No. 2 pump is rapidly increased and constant压控制。 Pressure control.

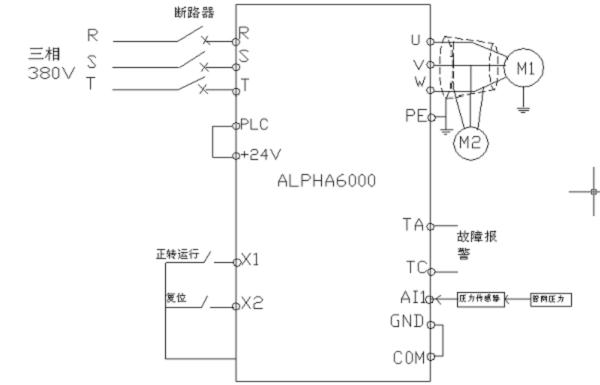

Working principle: The pressure of the water injection pump on the secondary control circuit is given by the 1-3K potentiometer, and the pressure feedback value is input from the IS end by the pressure transmitter in the form of 4-20MA current to implement closed-loop control. The start and stop of the inverter consists of FWD, XI, COM terminals to form a three-wire operation mode and is a logical start and stop of duplex control. Connect 0-10V DC voltmeter to FM and GND to observe the output frequency of the inverter. A and C are connected to the flashing alarm, and it will alarm in time if the inverter fails.

Functional block diagram