Yuxi Xinxing Iron and Steel Co., Ltd. is a steel conglomerate that Kunshan Iron and Steel Group has implemented in the province’s multiplication plan and made full use of the resource advantages of Yuxi to expand in Hongta District.

I. Overview

Yuxi Xinxing Iron and Steel Co., Ltd. is a steel conglomerate that Kunshan Iron and Steel Group has implemented in the province’s multiplication plan and made full use of the resource advantages of Yuxi to expand in Hongta District. The company was completed and put into production on March 15, 2005. The main products are: rectangular continuous casting billet, slab, hot-rolled ribbed steel bar, medium and wide band, etc. The products sell well in Yunnan, Sichuan, Chongqing, Guangdong and other markets. Under the excellent situation of continuous improvement of the market economy system, acceleration of reform and opening up, and development of the western region, Yugang seizes opportunities to accelerate development, widely absorbs the successful experience of domestic and foreign excellent steel companies, optimizes the process structure, and vigorously promotes technological progress and energy conservation The work of reducing consumption and cleaner production has made the structure of steel products more reasonable, and the market competitiveness has been significantly enhanced. A qualitative leap has been achieved in the modernization, intensive and efficient industrial process. Energy conservation and environmental protection and economic development have made greater contributions.

2. Production process

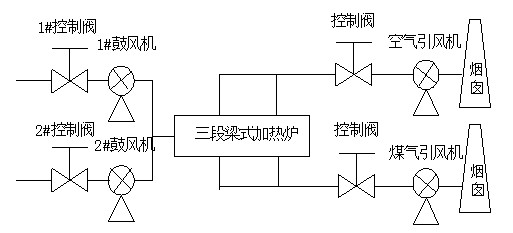

The medium and wide-band operation area adopts a three-section beam heating furnace. The air supply volume is adjusted by the air inlet valve. The blower is designed for one use and one standby. It operates 24 hours.

In normal production, when the heating cold steel is damaged, the blower inlet valve opening is 70~80%, and the supply air pressure is maintained at about 4.5kPa to ensure the furnace heating temperature.

When the heating hot steel is damaged, the blower inlet valve opening is 50~60%, and the supply air pressure is maintained at about 4.5kPa. When the heating furnace is insulated, the supply air demand is less, and the inlet valve opening is reduced accordingly. The wind pressure is kept at about 4.2kPa.

Gas exhaust and air exhaust air volume are regulated by air inlet valve. In normal production, when the heating cold steel is damaged, the gas exhaust fan air exhaust inlet valve opening is 70-85%. In normal production, the heating steel is damaged, the gas exhaust fan air exhaust fan inlet valve opening is 50~60%, when the heating furnace keeps heat, the opening of the inlet valve of the two fans is 30%.

The air inlet valve of the air exhaust fan is adjusted according to the steel rolling speed to ensure the uniform temperature in the furnace. The exhaust temperature of the two is controlled within 100 ℃, and the alarm is over 180 ℃. The heating furnace fan process is simple The picture is as follows:

Three, transformation plan

The three-section beam heating furnace blower, gas induced draft fan, and air induced draft fan, because the selection of the motor and fan is based on the maximum production capacity of the heating furnace, because the actual production capacity has not reached the maximum production capacity, the adjustment gate, The method of increasing the fluid resistance of the pipe network to achieve the flow control, so the system has low efficiency, large power consumption, and serious waste of electrical energy.

Due to the continuous and stable air supply required during normal production, the air volume and air pressure do not change much. At this time, the throttling loss can be eliminated by the adjustment of the fan speed by the frequency converter, and at the same time, the operating efficiency of the fan can be improved, although due to the load rate of the motor The drop will reduce its operating efficiency, but due to the large decrease in the operating power of the fan, the loss of the motor is also reduced, and ultimately the operating power of the motor is greatly reduced, thereby achieving the purpose of saving electricity.

1 Variable speed principle:

According to the basic principles of electromechanics, the speed principle of the motor satisfies the following relationship:

n=(1-s)60f/p

In the formula: P-motor pole pair number

F-motor operating frequency

S-slip

It can be seen from the formula that the synchronous speed N1 of the motor is proportional to the operating frequency N of the motor. Since the slip S is generally smaller than 0.05, the actual speed N of the motor is approximately equal to the synchronous speed N1 of the motor, so the power supply of the motor is adjusted Frequency F can change the actual speed of the motor.

And changing the frequency must change the supply voltage, the electromagnetic relationship produced by the AC motor:

E=4.44fwØ

In the formula: E-motor electromotive force

f-stator frequency

w-winding coefficient

Ø-Air gap main flux

When adjusting the speed of different frequency motors, we hope that the main magnetic flux Ø is constant, and the u/f curve is kept constant. Therefore, when the frequency is changed, the power supply voltage also changes.

2 Principle of power saving by fan speed regulation:

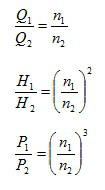

Due to the complexity of the fluid inside the fan, theory alone cannot accurately calculate their performance. The operating conditions of the fan can only be calculated by means of experiments and simulations by relying on similar theories in fluid mechanics. When the similar law is applied to the same fan running at different speeds, the following formula can be obtained:

从上式可以看出,流量与转速成正比,压力与转速的平方成正比,轴功率与转速的立方成正比,所以降低转速可以大幅度减少耗电量。风机的节电原理就是用调速装置来代替风门调节流量,减少节流损失,节约电能。风机是用来传送气体的机械设备,风机是把电动机的轴功率转变为机械能的一种机械,它们的启动力矩都较小,负载轻,具有很大节能潜力。

3 改造方案:

加热炉鼓风机目前的控制方式主要根据加热炉助燃风量的需求,空气引风机、煤气引风机主要根据引风温度和炉膛温度通过调整阀门开度来实现。由于助燃鼓风机和引风机工艺较为简单,没有必要做闭环控制,改造方案考虑在采用变频器后保持进风阀全开,根据生产需要人工操作调节风机转速。系统可随时随意改变引风量,以适应的变化,保持风机的正常经济运行,达到稳定控制、方便操作、节约能源的目的。

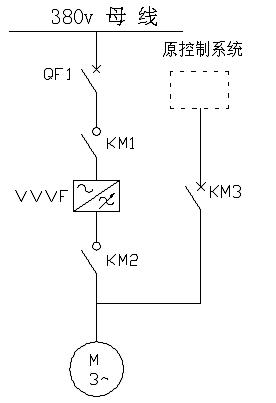

此外,为了保证系统的可靠性,鼓风机引风机现有的控制设备和运行方式仍将保留,控制回路上设计工频/变频运行切换选择,工/变频选择由人工切换操作,实现助燃离心风机在工频或变频运行。因加热炉鼓风机为一用一备,变频改造采用一拖二变频控制方式,设置1#、2#风机手动切换功能。

Main circuit diagram

In order to reduce the labor intensity of the on-duty workers, after the transformation, the start/stop, combustion/transition switching, and speed control of the combustion air blower and induced draft fan are both centralized and remote. The existing PLC computer control system is used, and the existing PLC is used. The standby point of the module increases the speed control operation function of the blower and the induced draft fan and the display function of the output frequency and output current of the inverter by modifying the program in the fuel control computer control system.

4. Analysis of running power saving effect

Take gas induced draft fan as an example

Figure: Inverter in operation

5. Other effects produced by the application of frequency converter

1 Reduced maintenance

Regardless of the process conditions after frequency conversion speed regulation, the system can be operated at any time by adjusting the rotation speed at any time. Due to the slow start and the reduction in rotation speed, the life of many parts is correspondingly extended, and the pipeline is greatly reduced. Impact, saving a lot of maintenance costs.

2 Reduced impact on the grid

After the inverter is used, the system achieves soft start. The starting current of the motor is much less than the rated current. The start time is correspondingly extended. There is no impact on the power grid, which reduces the mechanical damage of the starting machine torque to the motor and effectively extends the service life of the motor.

3 Improved working environment

Under full production process requirements, by reducing the speed of the fan, the fan's dry noise is reduced, especially when the furnace is commutated, the sudden load change causes huge dry noise, and the inverter's current limiting function reduces the fan's sudden load. The speed, the fan noise reduction is quite obvious. Greatly improved the working environment of employees.