The AC motor frequency conversion speed regulation is superior to the traditional DC motor speed regulation, and is also superior to the voltage regulation speed regulation, variable pole speed regulation, cascade speed regulation and other speed regulation methods. It is characterized by smooth speed regulation, wide speed regulation range, high efficiency, good structure, simple structure, hard mechanical characteristics, complete protection functions, stable and safe operation, and the best speed parameters in the production process, which is the ideal speed regulation the way.

I. Overview

In China's sugar industry, many important production equipment are high-energy consumption equipment. The power of the equipment cannot be separated from the speed regulation. Due to the technical conditions at the time of design, the drag speed of many equipment is mostly designed at the time of design. Adopting energy consumption adjustment, AC motor frequency conversion speed regulation is a new technology developed on the basis of modern microelectronics technology. It is not only superior to traditional DC motor speed regulation, but also better than voltage speed regulation, variable pole speed regulation, cascade The speed regulation methods such as speed regulation are superior. It is characterized by smooth speed regulation, wide speed regulation range, high efficiency, good structure, simple structure, hard mechanical characteristics, complete protection functions, stable and safe operation, and the best speed parameters in the production process, which is the ideal speed regulation the way.

Application practice has proved that AC motor frequency conversion speed regulation can generally save about 30% of electricity. At present, industrial developed countries have widely adopted frequency conversion speed regulation technology, and it is also a new technology of power saving that is mainly promoted by the state in my country. Frequency converters are used in fans, water pumps, squeezers, centrifuges and other loads in the sugar industry, and can achieve significant energy-saving effects.

two. working principle

1. Working conditions of the original water supply system

The original water supply system is composed of two pipeline network systems. The first pipeline water supply pumps are six, and the pump motors are: 110KW five, 75KW one; the second pipeline water pumps are six, and the pump motors are: 155KW five. Taiwan, one 220KW. The pump switching depends on the pressure personnel to switch according to the pressure. The water pressure changes greatly with the change of production water consumption and the switching of the pump unit. The switching of the pump unit has a great impact on the power grid. According to the production process, the water pressure and The flow rate needs to be adjusted by opening the return valve.

2. Frequency conversion energy-saving transformation plan

It can be known from the above system working conditions that the system is suitable for frequency conversion energy-saving transformation. The transformation scheme is as follows:

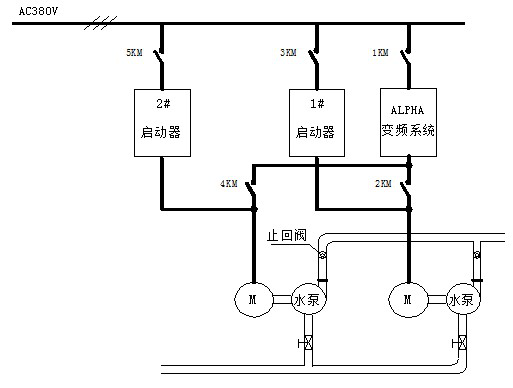

The system part adopts frequency conversion control. A pressure sensor is installed on each pipe network to instantly detect the water pressure of the pipe network. The frequency conversion control system automatically adjusts the speed of the pump motor according to the change in production water consumption to control the water supply of the system to ensure the water pressure of the pipe network. Constant. The first pipeline network is controlled by 110KW frequency conversion energy-saving system, two pump motors are used, one is used and the other four are controlled by power frequency; the second pipeline network is controlled by 220KW energy-saving frequency conversion system, one 220KW water pump motor and one 155KW water pump motor , One for one and one for standby, the remaining four sets are controlled by power frequency. After the transformation, the power-saving effect is remarkable, and the constant-pressure water supply greatly improves the production process. The control chart of the transformation system is as follows:

a Pump characteristics and parameters:

The power used purely for pumping is called effective power

Effective power=(1000QH)/(75×60/0.736)=QH/6.11(kW)

In the formula, Q is the flow rate (m3/min); H is the total head (m).

The weight of 1m3 of water set in the head is 1000kg, so: the shaft power of the pump = (effective power) / the efficiency of the pump (kW)

Motor output power=(1.05~1.2)×shaft power (kW)

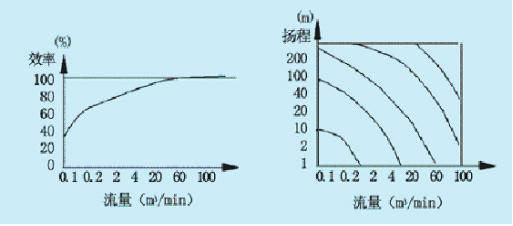

Due to the different pump head size and pump type, the efficiency of the pump cannot be determined in general. The approximate efficiency curve of the general standard pump

as shown in picture 2.

In view of the error in the design and manufacture of the pump, the output power of the motor should have a margin of 5 to 20% compared to the calculated value of the shaft power, and then the motor power is obtained according to the flow rate and head. Figure 3 is the flow rate and head characteristic curve .

Fig. 2 Efficiency of general standard pumps Fig. 3 Flow and head characteristic curves

b Water resistance characteristics of pipe network

When the water resistance R of the pipe network remains unchanged, the relationship between the water volume and the over-water resistance is uncertain,

That is, the water quantity Q and the water resistance h change according to the law of resistance, and its expression is:

![]()

In the formula, H—water resistance R—water resistance coefficient.

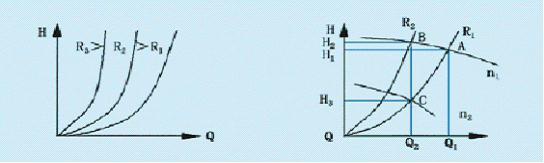

The relationship curve of H=f(Q) is the characteristic curve of water resistance, which is in the shape of a parabola, as shown in Figure 4. It can be seen from Figure 4 that the greater the water resistance coefficient R, the steeper the curve, that is, the greater the resistance to over-water.

c Energy saving principle of pump speed control

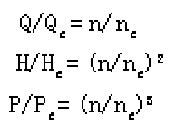

It can be known from the fluid mechanics that the water quantity Q is proportional to the first power of the speed, the pressure H is proportional to the square of the speed, and the power P is proportional to the cube of the speed.

In the formula: Qe—rated wind of fan and pump

(flow;

He—rated pressure of fan and pump

Pe—rated power of fans and pumps;

ne—Rated speed of fans and pumps.

It can be seen from the above formula that if the efficiency of the pump is fixed, when the required water volume is adjusted to decrease, the speed can be reduced proportionally. At this time, the shaft power of the pump is reduced by a cubic relationship.

In addition, according to the relationship between the characteristic curves of the pumps and the water resistance characteristics, the energy-saving effect of the fans and pumps can also be clearly seen. Figure 5 is a schematic diagram of the principle of energy-saving of speed regulation of fans and pumps. Curve H in the figure is the H-f(Q) curve at constant speed. Its water resistance and wind resistance characteristic curves R1 intersect with point A. The corresponding air volume is Q1.

At this time, the rectangular area enclosed by the shaft power Q1AH1Q of the fan and the pump is proportional to the area. When the baffle or valve is used to reduce the air volume from Q1 to Q2, the new wind resistance and water resistance characteristic curve H intersects at point B. At this time, the fan shaft power is proportional to the rectangular area enclosed by Q2BH2Q. If the speed regulation method is used to reduce the speed of the fan and water pump to n2, the corresponding fan characteristic curve H and the wind resistance characteristic curve R2 intersect at point C. At this time, the rectangular area enclosed by Q2CH3Q, which is proportional to the fan shaft power, is significantly reduced, indicating that the shaft power drops a lot and the energy saving effect is obvious.

Fig. 4 Water resistance characteristic diagram Fig. 5 Schematic diagram of water pump speed regulation and energy saving

3. System configuration

1. Constant pressure water supply function

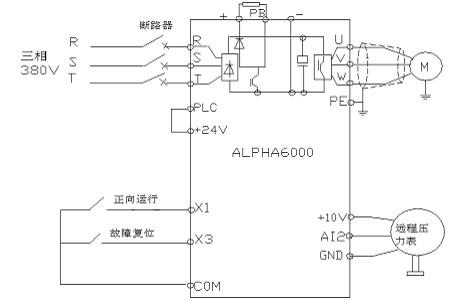

The 6000 frequency conversion system has a built-in PID regulator. The pipe network remote pressure gauge instantly detects the pipe network pressure and converts it into a 0~10V voltage signal, which is directly sent to the inverter analog voltage input port to set the given pressure value, PID parameter value, inverter Control the output frequency after the built-in PID operation. The system parameters can be adjusted during actual operation to make the system control respond quickly. The pressure of the pipe network can be arbitrarily set according to the production process. The frequency conversion system automatically follows the control to keep the pressure set by the pipe network constant, which is both energy-saving and sufficient for the production of sugar. The wiring diagram is as follows:

2. Switching instruction of pump unit

The system can instantly detect the water pressure of the water supply pipe network. When the existing pump unit cannot meet the production water demand or exceeds the production water demand, the system can automatically send out or cut off the pump group instructions, give the sound and light switching pump group alarm, and indicate the duty Personnel switch to the pump unit to ensure the need for production water.

3. Industrial frequency switching function

The reliability of the water supply system of the sugar industry is high. Once the failure will affect the whole production, it will have a serious impact on the whole production. Therefore, the system is equipped with a frequency conversion switching function. Under normal circumstances, the system runs in the state of frequency conversion and constant pressure water supply. When the frequency converter fails or routine maintenance, it can immediately switch to power frequency operation and start the water pump with the original standby auto-coupling start-up system to ensure water supply. Continuity, the reliability of the entire system can meet the production requirements well. Two sets of starting systems are electrically interlocked to prevent misoperation and ensure the safe operation of the system.

4. Revenue after transformation

1. Extend the service life of equipment and pipe network and reduce the workload of system maintenance.

Due to the use of variable frequency and constant pressure control, the start of the water pump is soft start, eliminating the impact of the impact torque on the motor when the large motor is started. The impact of the water pump at start is greatly reduced. At the same time, because of the soft start and the water pressure is constant pressure control, it is eliminated Due to the water hammer effect on the pipe network during startup, the phenomenon of tube explosion no longer occurs. Therefore, the service life of the original equipment is extended, the failure rate is greatly reduced, and the workload of system maintenance is reduced.

2. Improve the quality of water supply and the reliability of the entire system.

After the frequency conversion constant pressure control system is adopted, the water supply pressure can be adjusted very smoothly, and the on-duty personnel can adjust and control the system more smoothly and freely. As the production process changes, the water supply pressure of the system can be easily adjusted. After the new system is adopted, the failure rate is greatly reduced, and the two sets of start-up systems can be used as backups to ensure the continuity of the system's water supply and provide a reliable guarantee for the economical optimization of the system.

3. Improve the power consumption of the factory.

After adopting variable frequency soft start, the impact of the original start system on the power grid is eliminated. The power factor of the new system can reach 0.95, the efficiency can reach 0.98, the system working current is greatly reduced, and the line loss is also greatly reduced, which improves the factory. The status of electricity consumption.

4. The energy saving effect is remarkable, and the economic benefit is considerable.

In order to maintain the water pressure is basically constant when the original system is running, in addition to the need to continuously switch the pump unit repeatedly, a small range of adjustments need to be made using the return valve. The switching of the pump will also consume power in addition to the impact on the power grid. The return valve adjustment is basically Will not reduce the power consumption of the pump. After adopting frequency conversion, the frequency conversion pump set can automatically adjust the speed of the water pump motor according to the water pressure required by the production, to keep the pipe network pressure constant, the frequency conversion pump set has a wide adjustment range, the pump set switching times are greatly reduced, and the system energy saving effect is remarkable On average, the power saving rate of the entire system is about 30%, and the economic benefits are considerable.

5. Reduce the work intensity of the staff on duty

After the original system is modified, the water pressure of the pipe network is automatically detected and controlled, and the return valve does not need to be adjusted. The switching of the pump unit has an audible and visual alarm indication. The on-duty personnel will not worry about the failure to switch the supply pump unit in time and open the return valve. Low or high water pressure affects production accidents.