Since the industrial revolution 200 years ago, urban domestic sewage treatment has received more and more attention. The urban sewage treatment rate has become an important indicator of whether a region is civilized or not.

I. Overview

Since the revolution, people have paid more and more attention. The urban sewage treatment rate has become an important indicator of whether a region is civilized or not. Over the past 200 years, urban sewage treatment has evolved from primitive natural treatment and simple primary treatment to the use of various advanced technologies for advanced treatment of sewage and reuse. The treatment process has also developed from traditional activated sludge method and oxidation ditch process to A/O, A2/O, AB, SBR (including CCAS process) and other processes to meet different effluent requirements. Compared with foreign developed countries, urban sewage treatment in my country started late, and the current urban sewage treatment rate is only 6.7%. While we vigorously arouse foreign advanced technology, equipment and experience, we must combine our country's development, especially the local actual conditions, to explore an urban sewage treatment system suitable for our country.

Combined with the actual situation in my country, and referring to advanced foreign technology and experience, the construction of urban sewage treatment plants should conform to the following development directions:

1 Total investment province. my country is a developing country, and the funds required for economic development are very large. Therefore, strict control of total investment is of great benefit to the national economy.

2 Low operating costs. The operating cost is an important factor for the normal operation of the sewage treatment plant and one of the main indicators for judging the pros and cons of a set of processes.

3 Land-saving province. my country has a large population, and its per capita land resources are extremely scarce. Land resources are an important factor in the development and planning of many cities in my country.

4 Nitrogen and phosphorus removal effect. With the eutrophication of large-scale water bodies in my country, the denitrification and dephosphorization of sewage has become an urgent problem. The newly implemented National Comprehensive Wastewater Discharge Standard (GB8978-1996) in our country also clearly stipulates that it applies to all pollutant discharge units, and very strictly regulates phosphate discharge standards and ammonia nitrogen discharge standards. This means that the vast majority of urban sewage treatment plants will consider nitrogen and phosphorus removal in the future.

5 Organic combination of modern advanced technology and environmental protection engineering. The emergence and improvement of modern advanced technology, especially computer technology and automatic control system equipment, provide strong support for the development of environmental protection projects. At present, most of the sewage treatment plants in developed countries use advanced computer management and automatic control systems to ensure the normal operation of the sewage treatment plant and stable qualified effluent, but my country is still relatively backward in this regard. Computer control and management will also be the development direction of my country's urban sewage treatment plants.

2. Sewage treatment process and frequency conversion feasibility

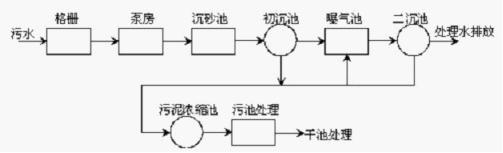

1 Process of original sewage treatment system

The mature experience and development trend of domestic and foreign sewage treatment plants are compared and compared. Currently, most domestic and foreign urban sewage treatment plants use primary treatment and secondary treatment.

b

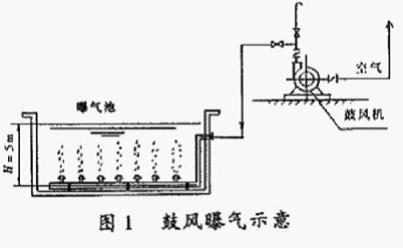

It is the core equipment of sewage treatment that operates 24/7

2 Feasibility of frequency conversion transformation

Variable frequency speed regulation is a

3 Frequency conversion energy saving principle

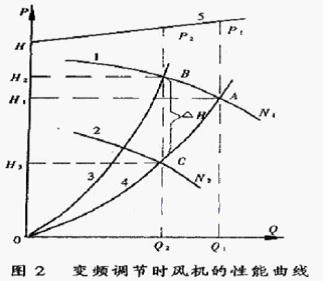

Figure 2

Curves 1 and 2 represent the pressure-flow curve during speed regulation

Let point A be the maximum operating point of the fan. When the air volume needs to be reduced from Q1 to Q2, if the throttle adjustment method is used, the operating point is from A to B, and the air pressure is increased to H2. It can be seen from the figure that the shaft power P2 decreases, but the reduction is not too much. If the frequency conversion adjustment method is adopted, the operating point of the fan changes from A to C. It can be seen that under the same air volume Q2, the wind pressure H3 will drop significantly, and the power P3 will decrease significantly with it. The saved power loss △P=△HQ2 is proportional to the area BH2H3C in the figure.

a From the above analysis, it can be seen that frequency conversion adjustment is an efficient adjustment method. The blower adopts frequency conversion adjustment, which will not cause additional pressure loss, and has a significant energy saving effect. The adjustment air volume range is 0% to 100%, which is suitable for a wide adjustment range and often under low load. However, when the fan speed decreases and the air volume decreases, the wind pressure will change greatly, according to the law of fan proportionality:

Q1/Q2=(n1/n2), H1/H2=(n1/n2)2, P1/P2=(n1/n2)3

Know

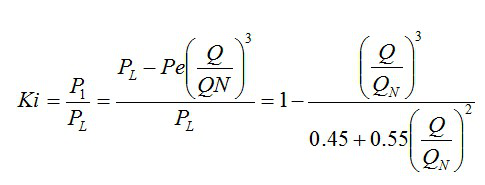

①

②

P2=(0.8)³×P1=0.51P1, saving 49% electricity.

b Because the power has a cubic relationship with the speed, the greater the speed change, the power consumption will decrease geometrically.

c According to GB12497 "Economic Operation of Three-Phase Asynchronous Motors"

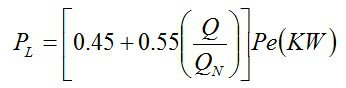

Fans and pumps, using baffles to adjust the flow corresponding to the input power of the motor

式中:

QN

In the formula: Ki is the power saving rate, P1 is the power saving

The above formula can be used to estimate the power savings. According to the original working conditions, for the fan using the inlet guide vane, the energy saving effect of the inlet guide vane at a small angle opening is not much different from that of the inverter, that is, the energy saving effect of the frequency conversion control is quite small when the opening is 10%. .

4 Actually generated economic value and its estimation

a The bypass opening is 30%, and the power saving rate is estimated when the flow is 70%:

1-((0.7)3/0.45+0.55×(0.7)2)=52%

b. Estimated power consumption per unit of the original industrial frequency per month: 160×0.7×24×30=80640 KWH

c. Monthly power saving per unit after frequency conversion: 80640×52%=41933 KWH

d After frequency conversion, each unit saves electricity bill every month

Conclusion: Each set of frequency conversion energy-saving cabinets offer: 192,000 no; investment recovery period: about June

3. Operating conditions of the original equipment

1 Device parameters

a Nanning sewage treatment plant has a total of 3 centrifugal blowers, model: 1TYC27

b The matching three-phase asynchronous motor model is: Y2-315L1-2-160KW, 2-pole motor, rated speed

Speed 2975RPM.

c

2 Blower working condition in sewage treatment

3

,,

4 Water and other issues

The pipeline is broken or collapsed, damaged and fixed, and will increase the load condition of the incoming transformer. After adopting frequency conversion adjustment, the process of starting or stopping can be prolonged by extending the time of rising and falling. Even during the operation, the wear of the working frequency can be greatly reduced, and the working life of the equipment will be greatly extended.

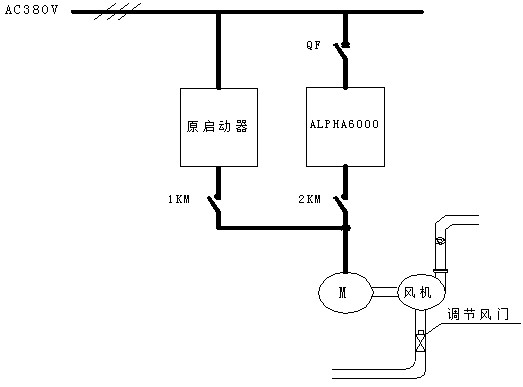

Four, frequency conversion plan

V. User benefits

1 High-efficiency and energy-saving operation with considerable energy-saving effect. After the frequency conversion reform with a short return on investment period, the blower can adjust the air supply according to the process needs, and save energy after frequency conversion and speed regulation.

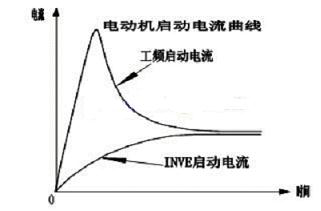

2 The motor is really soft-loaded under load to reduce impact. After using frequency conversion adjustment, due to the use of SPWM technology, the real soft start and buffer stop are realized, the damage of the starting current to the motor and other equipment is basically eliminated, and the service life of the equipment is greatly extended.

3 Extend equipment life. After the frequency conversion adjustment is adopted, the process of starting or stopping can be extended by extending the time of rising and falling. Even during the operation, the working point can be selected by skipping the working point that is easy to cause the equipment to vibrate. The stress on the pump blade, one-way valve and pipeline system is greatly reduced, the wear of the bearing is greatly reduced, and the working life of the equipment will be greatly extended.