The principle of frequency conversion constant pressure water supply system is mainly composed of ALPHA6000 series inverter, Mitsubishi FX2N series PLC, pressure sensor, power, control circuit and pump group.

1. System Structure

The principle of frequency conversion constant pressure water supply system is as follows: it is mainly composed of 6000 series inverter, Mitsubishi FX2N series PLC, pressure sensor, power, control circuit and pump group.

2. Working principle

1. Manual

Press the button to start and stop the pump, and control the start and stop of the 1#~3# pump according to the need. This method is mainly used for equipment debugging and maintenance

2. Automatic

The condition is met, the work starts, the 1# pump frequency conversion starts, the pump speed increases with the increase of the output frequency of the inverter, when the frequency of the inverter reaches 50HZ, the water pressure does not reach the set value at this time, the inverter detects the upper limit frequency and Output a switch signal to PLC, after a period of delay, the 1# pump quickly switches to power frequency operation, and the frequency of the inverter is reduced to 0HZ. Then the 2# pump starts with frequency conversion. If the pressure has not been reached, the 2# pump is switched to the power frequency. 3# pump frequency conversion start, always keep one pump frequency conversion operation during operation.

When the pressure reaches a certain value, the inverter will output 0HZ, and the inverter will output a lower limit frequency to the PLC, and the PLC will cut off the 1# power frequency pump. If the pressure setting value is reached at this time, the inverter output will be 0HZ, and the lower limit signal will be output to The PLC cuts off the 2# power frequency pump, and only the 3# pump operates with frequency conversion to maintain the pressure. If you need to add a pump, switch from the 3# pump to start circulation, so that the pipe network pressure is always kept constant regardless of the change in water consumption, and the running time of each pump is basically the same, extending the service life of the pump and bringing convenience to maintenance and repair.

3. System configuration

1. Control chart

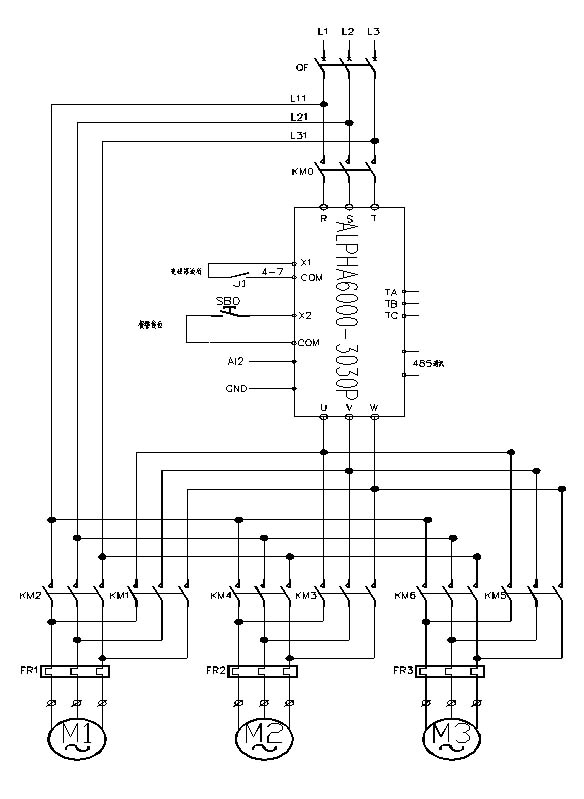

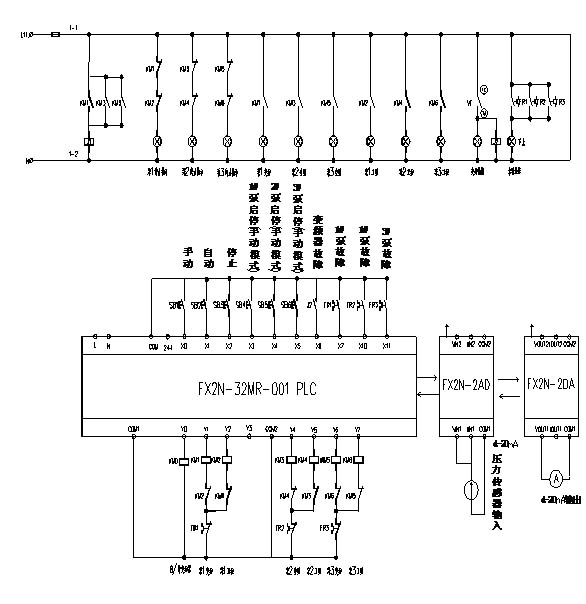

2. Wiring diagram of control system

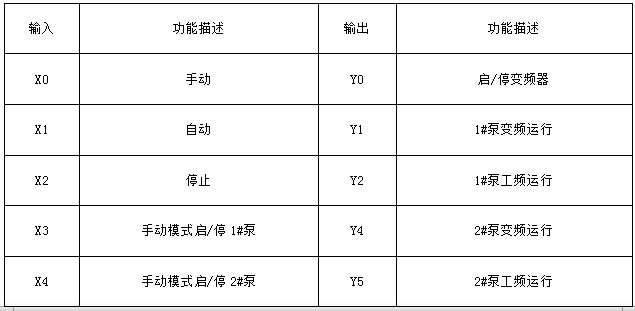

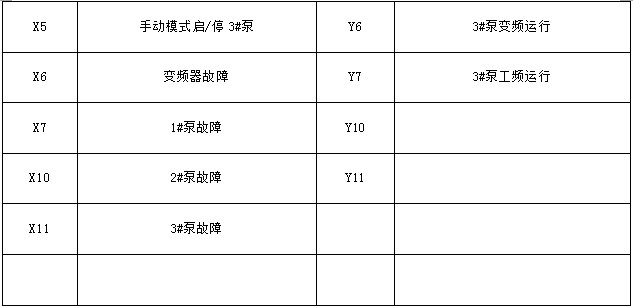

3. I/O terminal assignment table

Four, system advantages

6000 series inverters are fully compatible with Mitsubishi PLC. If higher requirements are required, the 6000 series communication protocol makes the control system more convenient and concise, and improves the degree of automation.