China is the country of origin of tea. China’s application of tea dates back to 4,000 years ago. Since the 1980s, China’s tea processing technology has rapidly developed toward mechanization. Various tea-making machinery have been successfully developed and developed. , And gradually apply and produce.

I. Overview

China is the country of origin of tea. China’s application of tea dates back to 4,000 years ago. Since the 1980s, China’s tea processing technology has rapidly developed toward mechanization. Various tea-making machinery have been successfully developed and developed. , And gradually apply and produce. So far, 90% of my country's bulk tea has been mechanized, and more than 50% of famous tea has been mechanized.

However, although the domestic tea-making mechanization operation technology has made great progress, the automation and continuity of tea-making machinery in Chengdu is still low, and there is indeed a big gap compared with the mechanization of the food industry. The development of industrial production technology generally needs to go through five stages, namely, the mechanization stage, the primary automation stage, the automation stage, the data stage, and the advanced automation stage (unmanned). At present, China's tea making technology is basically still in the first place. In the second stage, there is a big gap compared with foreign countries. Therefore, the automatic transformation of the tea machine is imminent.

2. Working principle

The main mechanism of tea kneading machine is composed of kneading disc and frame, kneading barrel and pressure device, transmission mechanism and so on. The kneading bucket is a container for loading the kneading leaves, which is fixed on the kneading bucket frame and driven by the crank arm. During the operation, the kneading drum is filled with green leaves, and the kneading chamber composed of the kneading drum, the kneading drum cover and the kneading disk is driven by the motor and the transmission mechanism. The pressure of the lid of the kneading bucket, the reaction force of the kneading disc, the kneading force of the ribs and the pressure of the side of the kneading bucket are gradually twisted into strips, and some leaf cells are broken and the tea juice overflows to achieve the purpose of twisting.

The automatic control system of the kneading machine includes the following parts:

1. Kneading barrel rotation speed control: The original tea kneading machine has a gear reduction mechanism, and the output rotation speed is a fixed value, which cannot be adjusted. However, different tea types may require different speeds of twisting, although only a slight change also reflects the fineness of tea processing. After the automation transformation, the speed control can be realized by AC motor frequency conversion speed regulation technology

2. Pressure control: Pressure control is the key to the entire control system. The lifting of the lid is used to control the pressure on the tea in the bucket. The original system is manually controlled by a hand wheel to pressurize. After the automation transformation, the hand wheel rotation is changed to the motor to drive the screw to rotate, and the motor can have PLC given instructions and frequency control.

3. Rolling process control: Process control is actually time control. The twisting process can be divided into "light-heavy-light" three processes. The time value of each process can be flexibly grasped and determined according to the twisting process. Before processing, the time parameters of each process are input into the upper computer, and then the PLC controls the motor operation according to the input parameters to provide the required speed and pressure.

4. Upper and lower leaf control: The tea outlet door is in the center of the bottom of the kneading barrel. The original tea door switch is manually opened and closed. During the transformation, automatic switch control can also be achieved by the motor drive.

3. System configuration

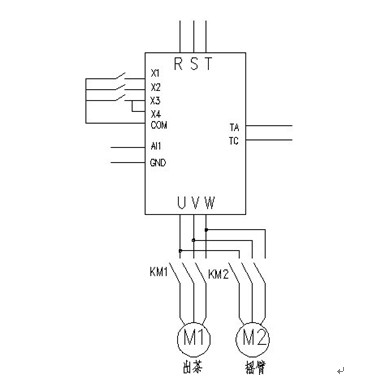

In this system, 6000S frequency converter is used, and two motors are controlled by one frequency converter to switch between different operating modes. The two do not work at the same time. The rocker motor works in torque mode, and the constant torque control pressure is given to provide stable pressure. Working in speed mode, the function is to open and close the tea door.

Four, system advantages

Traditional twisting and twisting system, quality management and quality control are only guaranteed by manual experience and routine review and physical and chemical inspection, while the automatic twisting and rolling control system composed of PLC and inverter has high degree of automation, simple operation, saves labor cost and improves at the same time Production efficiency, it is worth promoting.