How to excite vibration and how to adjust the vibration frequency has always been a concern of brick machine manufacturers. Since the frequency conversion technology is widely used, the vibration forming method of adjusting the motor speed by the frequency converter to drive the vibrator has been paid attention by many brick machine manufacturers. The brick machine can preset different vibration frequencies and vibration accelerations according to the classification of products. The control of starting, accelerating, decelerating and stopping is flexible, which greatly enhances the forming quality and performance of the products.

I. Overview

In the construction industry, commonly used wall materials in China can be divided into two categories, namely solid clay bricks and new wall materials, solid clay bricks (commonly known as red bricks) made of clay as the main material through sintering process, because of their process The equipment is simple and has a long history of use. For a long time, it has been the main wall material in China; it is made of industrial waste materials such as cement, sand and fly ash, coal gangue, slag and other construction wastes or construction waste through mixing, vibration, suppression and other processes. New non-clay bricks, building blocks and other new wall materials, similar new wall materials have been gradually promoted and popularized in China in recent decades, of which concrete blocks are the most commonly used. "Banshi" is the abbreviation for prohibiting the use, sale and production of solid clay bricks. Compared with new wall materials, solid clay bricks have unfavorable factors such as digging and destroying fields, wasting energy, and polluting the environment during the production process. Therefore, the country has issued many hard indicators and policies to encourage the use of new wall materials and gradually ban solid clay bricks. According to relevant national regulations, all cities (towns) in China have banned clay bricks since 2010, which provides huge market space for new wall materials.

2. Working principle

A fully automatic block forming machine is mainly composed of a belt conveyor, a vibration forming machine (host), a plate feeder, a brick out machine, a palletizer, a control cabinet, a hydraulic pump station, etc., where the vibration forming device is a block forming The core part of the machine, its performance directly determines the quality of the machine itself and the forming blocks.

Vibration technology is classified according to the position of the vibration source. The block forming machine can be divided into table vibration machine and mold vibration machine. The model where the vibration source directly acts on the vibration table is called a table vibration machine, and the model starts with "QT". The model where the vibration source is installed on the mold box is called the mold vibrator, and the model starts with "QM". Due to the advantages of large output and low average vibration power of block, the vibrator has become the mainstream model of domestic brick machine manufacturers. Taking a table vibrator as an example, the general vibrator is driven by an electric motor or a hydraulic motor. Two shafts with eccentric blocks in the vibrator produce opposite high-speed rotation. The horizontal centrifugal forces cancel each other out, and the vertical centrifugal forces cancel each other out. Superimposed to produce vertical directional vibration. When there are fewer shaped blocks, one vibration source can be set under the mold box; when there are more shaped blocks, two or more vibration sources can be set.

At present, the vibrator is directly driven by the motor, which has the following disadvantages:

(1) The motor is frequently started directly (3 to 4 times per minute), the starting current is large (5 to 7 times the rated current), the temperature of the motor is increased (above 70 degrees Celsius), and the bearing grease is easy to melt and cause damage to the motor;

(2) The contactor moves frequently, the passing current is large, and the contact is easy to age;

(3) When the grid voltage is low, it is difficult to start the motor under load;

(4) The running time of the motor every time is 2 to 4s, the average power factor is low, and the line loss is serious;

(5) When the motor is directly started, the mechanical shock is large, and the requirements for various mechanical accessories are high

How to excite vibration and how to adjust the vibration frequency has always been a concern of brick machine manufacturers. Since the frequency conversion technology is widely used, the vibration forming method of adjusting the motor speed by the frequency converter to drive the vibrator has been paid attention by many brick machine manufacturers. The brick machine can preset different vibration frequencies and vibration accelerations according to the classification of products. The control of starting, accelerating, decelerating and stopping is flexible, which greatly enhances the forming quality and performance of the products.

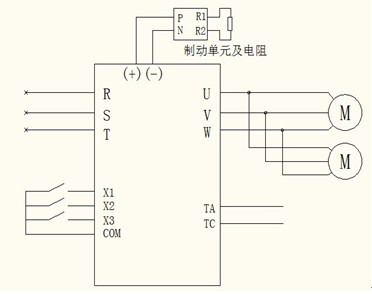

3. System configuration

The frequency converter is 18.5KW and drives two 7.5KW motors at the same time. It is controlled by PLC. The original system's contactor is directly omitted. Only need to set: external start, frequency setting (communication), acceleration time, deceleration time, multi-stage speed, The upper limit frequency is sufficient. At the same time, the fabric is frequency-converted and runs at the first speed set. After the fabric is completed, the vibrator is controlled to generate vertical synchronous vibration according to the frequency set on the interface, which realizes the working principle of low-frequency feeding and high-frequency molding. Obtain a good vibration effect.

Four, system advantages

Compared with the direct drive of the motor, the use of inverter technology in the vibration system has obvious advantages:

(1) The frequency regulation needs of the vibration system can be easily achieved to meet the production process requirements;

(2) Rapid acceleration and deceleration, saving molding time and increasing production capacity;

(3) Low starting current and less impact on the power grid;

(4) The motor starts smoothly and the mechanical shock is small;

(5) The low temperature rise of the motor is conducive to the long-term stable operation of the motor;

(6) High energy transfer efficiency, saving electricity;

(7) The masonry has good forming density and the surface is smooth and beautiful;

(8) The inverter has unique AVR function, which can output enough voltage to drive the motor to work even when the grid voltage is low.